Mirage Portable Machine Tools

•Mirage Portable Machine Tools:

Decades of engineering know-how combined with a continuing drive to innovate has resulted in a wide range of world-class portable machining equipment - each machine robust enough to handle the toughest of on-site machining challenges.

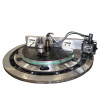

•Mirage Flange Facing Machines:

Mirage Flange Facing Machines from Enerpac cover diameters up to 161" (4089mm). These robust and accurate flange facers create a continuous groove spiral serrated finish – essential for achieving leak-free connections on many types of flange joint. Several flange facers can also be configured to machine an RTJ groove for ring type joint gaskets.

Since joining the Enerpac product portfolio, the technology used in our flange facers remains true to the tried and tested designs developed by Mirage Machines. Choose one and you’ll benefit from quick set up, easy operation, and repeatable precision.

•DL Ricci Clamshell Cutters and Accessories:

Enerpac Clamshell Cutters (split-frame cutters) are highly portable split frame lathes ideally suited for machining applications within new construction, decommissioning, component replacement, fabrication, and refurbishment industries. Choose from narrow body, mid-size and heavy-duty clamshell cutters, and from a wide range of accessories to extend the capabilities of each standard machine.

•Mirage Portable Milling Machines:

Mirage single axis, 2 axis portable milling machines from Enerpac are versatile machining tools that deliver workshop tolerances on-site. They remain true to the tried and tested technology and heritage of the Mirage Machines range of portable machine tools. The LMR range of portable mills are purpose-designed for machining heat exchanger division slots, but can also be used for “light” milling applications.

•Mirage Casing Pin Drilling Machines:

Casing pin drilling machines capable of drilling 2 lift pin holes in a single operation. Uses a swing gate mechanism for locking into the work piece. Used as a decommissioning solution when drilling and cutting and pipelines, conductors, caissons and multiple grouted strings.

•Mirage Orbital Milling Machines:

Mirage Orbital Milling Machines from Enerpac deliver fast material removal and precision flatness tolerances across large diameters. The two types within the Enerpac range are:

OM-Series Orbital Milling Machines – ideal for a variety of in-situ machining applications.

WP-Series Orbital Milling Machines - designed specifically for manufacturers of wind turbine blades and towers.

•Mirage Diamond Wire Saws:

Mirage Diamond Wire Saws from Enerpac are used for a wide range of tubular severance projects. Diamond wire rope saws provide an effective top side and subsea cutting method with the ability to quickly cut through dissimilar materials.

•Mirage Hot Tapping Machines and Line Stopping:

Hot tapping is a high-pressure intervention and the Mirage range of hot tapping machines from Enerpac can help towards a safe and effective solution. Industry-leading innovations used in our machines include a helical gear drive located as close to the cutting head as possible - ensuring maximum efficiency, along with rotary pressure seals, and four fixed feeds.

•Piping Isolation and Test Tools:

Positive isolation of process piping using Enerpac MITT Series Tools deliver a more cost-effective and quicker alternative than traditional hydrotesting and pipe flushing methods.

MITT-Series tools allow welding to be performed safely on hydrocarbon lines. This provides peace of mind of a positive pressurized hydrostatic isolation. Each of these combination tools can be used for both isolation and testing.

Up to 6 pipe schedules are covered per tool, and the lightweight construction means a crane is not required. The tools simply mount into elbows and tees and allow testing to take place on mismatched schedules.